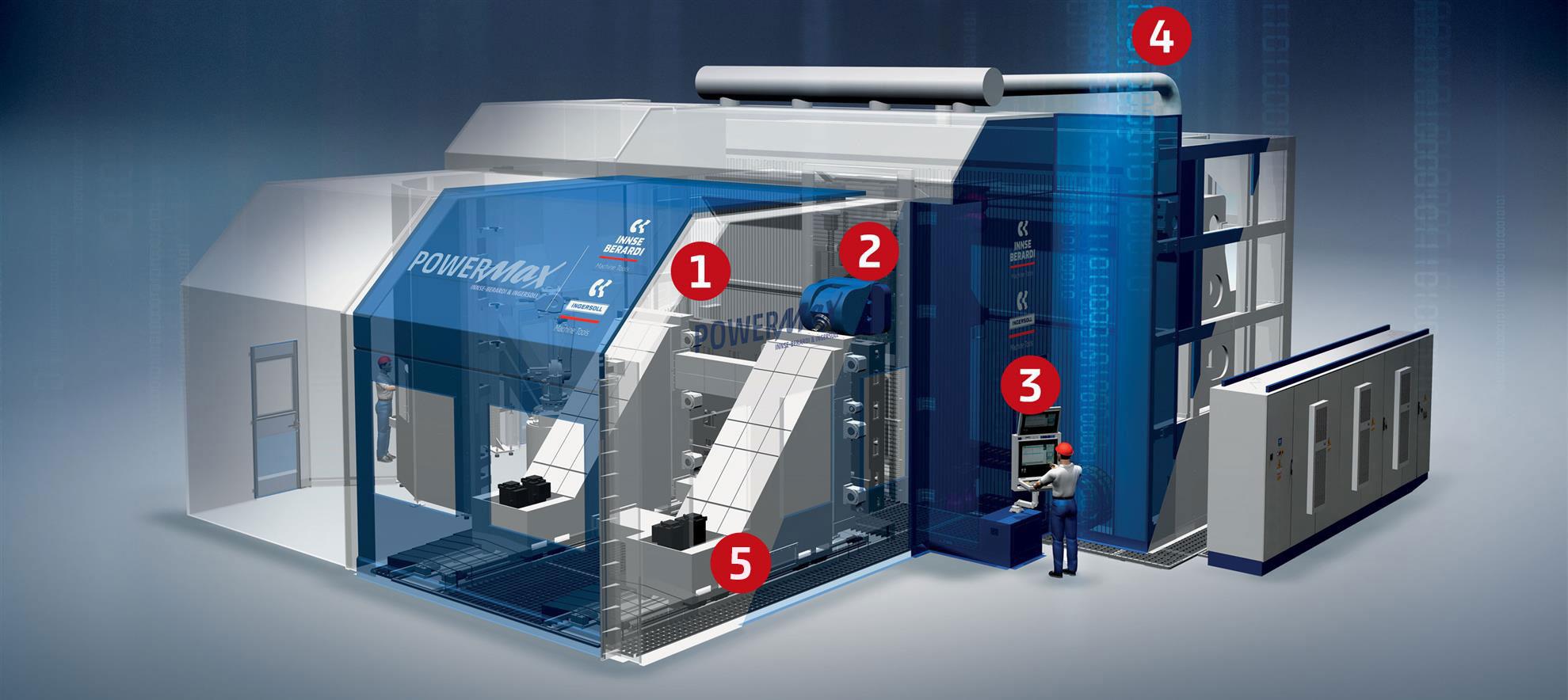

1

Multiple optical scales and sets of high torque, high power, coupled gear motors for each one of its X, Y, Z, C, A axes that confer PowerMax® a first natural frequency of 25Hz+ (Patent pending on X-Y KINEMATICS)

- Superior dynamic positioning accuracy in the entire large working envelope at all speeds and accelerations for constant chip removal rate throughout the entire milling volume (quality, capacity, productivity)

- Chatter-free, high-rate titanium removal with reduced cutting tool wear (productivity, quality, low OPEX, low TCO) ·

- Reduced inspection time and rework (low OPEX, low TCO)

2

With no ram, the large, thermally symmetric XYZ-C structure is designed specifically to minimize static

deflections throughout its travels

- Superior static positioning accuracy throughout the entire large working volume (quality and capacity)

3

Siemens Sinumerik One, Fanuc, Heidenhain controls: most powerful reliable and widespread, industrial CNCs

- Minimal user training, widespread responsive OEM assistance, industry standard (low OPEX, low TCO)

4

IBRM: Equipment Monitoring, Process Monitoring, Digital Twins, Remote Diagnostic, Preventative Maintenance

- Reduced maintenance cost, minimized downtime, continuous process improvement, digital parts certification (low OPEX, low TCO)

5

The front slide (Z axis) has been designed with hydrostatic guideways

- Minimal user training, widespread responsive OEM assistance, industry standard (low OPEX, low TCO)