Hawk™ is Ingersoll Machine Tools’ new Fiber Placement Module engineered for high productivity and high-reliability layups of large aero and space structures: wings, fuselages, rocket stages, fairings.

Designed to maximize reliability, ergonomics, and productivity while also offering extremely large working volumes, Hawk™ is uniquely positioned as the equipment of choice for high throughput applications.

With its unique bundle of short / untwisted tow path and ergonomic/modular subassemblies, Hawk™ provides a defect-free layup with minimal maintenance and effortless spool loading/threading.

Hawk™ can place a wide variety of fiber reinforced materials, from the most common to the most challenging, including epoxies, BMI, thermoplastics, carbon fiber, glass fiber, and more.

Programming, simulation, optimization, and diagnostics are performed through Ingersoll proprietary software.

Hawk™ is offered in 4 to 24 tow varieties (1/8”, 1/4”, or 1/2” wide) with these multiple configurations being automatically exchanged and operated to increase the quality and the productivity of your lay-up process.

Hawk™ size and configuration can be easily tailored and optimized to fit the customer’s process and meet their end-user needs.

Benefits

- Productivity

Reduce the manufacturing time guaranteeing high deposition rates (m/min - lbs/h) - Capacity

Layup large and extra-large structures - Feasibility

Layup mild curvature, locally flat surfaces using all main fibre-reinforced materials - Quality

Obtain a layup free of defects, with consistent and repeatable tolerances - Versatility

Possibility to add new manufacturing processes when they become necessary - High ROI/Low TCO

Limited Technology Acquisition Costs and Low Operating Costs

Module Configurations

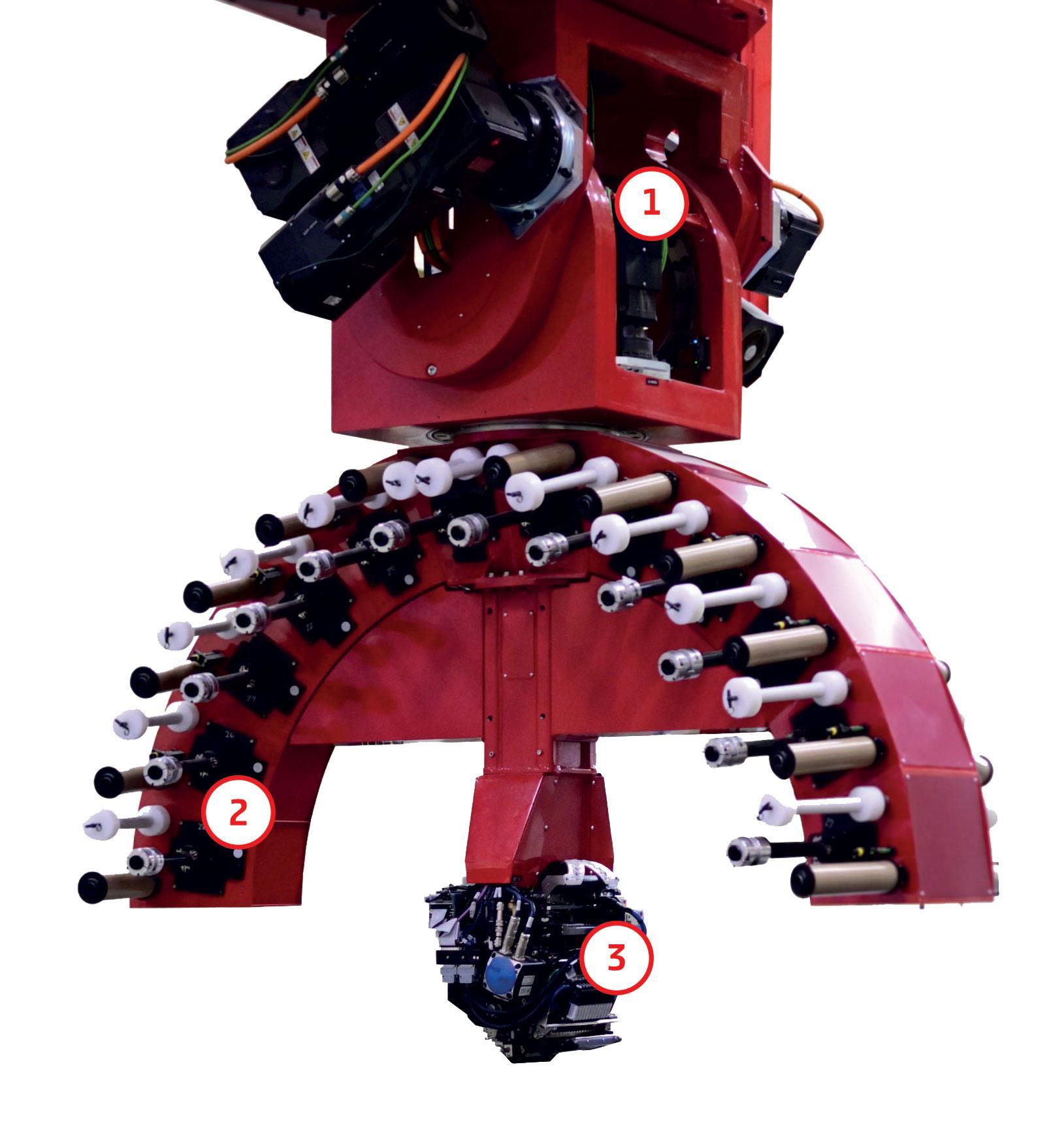

Each one of the different Hawk™ module configurations consists of 3 main subassemblies:

1. Wrists

The Wrist is Hawk™ 3 polar axes assembly (C, A, C1) that - summed to the 3 linear axes of the Mongoose™ Hybrid gantry (X, Y, Z) - turns the Hawk™ Head into 6 axes positioned end effector (point, direction, orientation and normal)1

Wrist (Rotary Axes):

| C | A | C1 |

|---|

Axis Designation | Roll | Bend | Roll |

Travel Range | +/- 225° | +/- 92° | +/- 185° |

Axis Feedrate - min/max | 0-20 RPM | 0-20 RPM | 0-20 RPM |

Acceleration Rate | 200deg/sec2 | 200deg/sec2 | 200deg/sec2 |

1 In the case of the Robotic FP™, the wrist polar axes are substituted by the robot’s 6 axes.

2. Creel

The Creel is Hawk™ spools storage and spools management subassembly. The Creel and Head together are rotating with Wrist axes and moving as a single unit in order to completely avoid tow-length-variability/tow-twisting between the Creel and the Head. Depending on the configuration selected, the Creel comes with:

- Short / untwisted tow path

- Effortless spool loading/threading

- Spools number: from 4 to 24

- Spool max size: 3” (ID) x 8” (OD) x 11” (width)

- Spool max weight: 15.5 lb

- Individual tow tension control

- Automated backing film material removal

3. Head

The Head is Hawk™ tow placement end-effector, capable of accurate deposition of a wide variety of fibre-reinforced materials, from the most common to the most challenging, including epoxies, BMI, thermoplastics, carbon fiber, glass fiber, and more.

The Hawk™ Head has been designed and is cooled to minimize contamination by carbon fiber and resin.

In addition, the Head is built with quick exchange and interchangeable components in order to minimize the time required for maintenance. Depending on the configuration selected, the Head comes with:

Tows numbers: from 4 to 24, actuated individually, symmetrically and asymmetrically | Miss Add and Cut Detection System (MCAD, Optional) |

Tows size: 1/8”, 1/4, 1/2” | Remote diagnostics and preventative maintenance through CMTnet™ (optional) |

Tows compaction force system: from 50 to 500 lbf (programmable) | In-situ inspection via Ingersoll ACSIS™ (Automated Composite Structures Inspection System) |

Tows heating technology: infrared (standard, and arc-flash, optional) | True bi-directional layup capability |

Tow catches modules to avoid pullback | 100 mm minimum add length |

Tow add module with quick exchange | 100 m/min max layup feed-rate |

Tow cut module with quick exchange | Add/cut tow end positional accuracy: ±2 mm at 40m/min |

Self-adjusting compliance travel: ±20 mm | Max tow acceleration: 4 m/sec2 |

Conformable set of tow compaction rollers | 0.5 degrees ply orientation accuracy |

Cooling for the components in contact with fiber to minimize resin build-up | Tool probing through touch-free laser system |

Feed axis tow wrap detection system | |