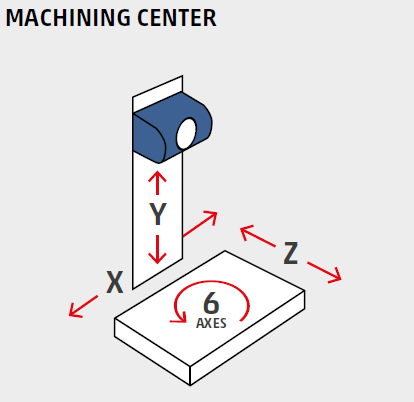

PowerMax®ST is a large working volume, 5 axes (6 in case the rotary table is selected), horizontal, subtractive manufacturing center for high-performance applications.

PowerMax®ST' s 3 linear axes travel along parallel sets of linear guides and optical scales mounted to thermally-symmetric sub-structures, driven with high-torque, high-power, coupled gear-motors controlled via Siemens, Fanuc, or Heidenhain CNCs. The same approach has been adopted for its C and A axes.

The design provides PowerMax® with superior static and dynamic positioning accuracies at high speeds and accelerations in its working envelope for a constant chip removal rate throughout the entire milling volume.

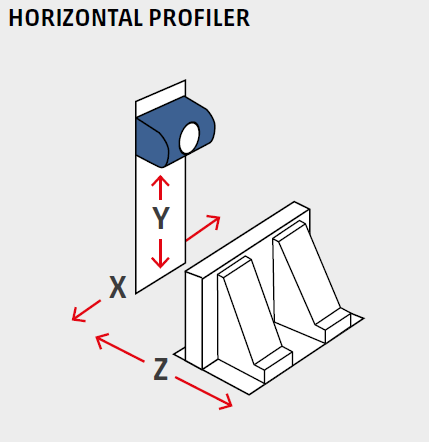

Kinematic Configuration is partially reversed

TWO MORPHOLOGIES

The milling head moves:

- horizontally along X with the column

- vertically along Y within the column

The part being milled moves horizontally along Z axis on the pallet.

In the 6 axes version, the pallet is replaced by a moving rotary table.

Benefits

- Feasibility

Manufacturing of complex geometry parts - Quality

Tight tolerances and surface finishing throughout the entire working volume - Capacity

Large milling volume - Productivity

Reduced machining time - High ROI/Low TCO

Low capital investment and low operational cost

Features