TURNING AND MILLING IN A SINGLE SOLUTION

"Vision" products are characterized by linear guides on the axes, speed, and high precision.

Specifically, this machining center is designed to combine under one single machine tool, turning and milling operations, automatic tool changer, automatic accessories, and the latest technology produced by Innse-Berardi.

The movable working crossbeam ensures that components of various sizes can be machined without sacrificing the rigidity of the system.

Its balancing and geometric correction is carried out thanks to two recirculating ball screws and 4 gear motors working with master-slave + gantry technology with the consequent advantages of accuracy and elimination of hydraulic balancing units, which are less responsive and need continuous periodic maintenance.

The particular nature of the machining required in the specific case led Innse-Berardi's engineers to propose a hybrid solution: hydrostatic table and Ram combined with the mechanical guides of the crosshead and cross axis of the head.

The large section of the adopted hydrostatic Ram allows vertical axis extension up to 2,500mm.

Technical features:

| Maximum distance between columns | 5.700 mm |

| Cross travel of the Ram (Y axis) | 8.000 (6.500+1.500) mm |

| Vertical travel of the hydrostatic Ram (Z axis) | 1.500 mm |

| Vertical travel of the mobile working traverse (W1-W2 axis) | 2.000 mm |

| Maximum power (S1) | 50 kW |

| Torque (S1) | 1.850 Nm |

| Maximum rotational speed (2 ranges) | 6.000 rpm |

| Working range Positioning C-axis | ±220 degrees |

| Discretion Positioning C-axis | 0.001 degrees |

| C-axis clamping torque | 10.000 Nm |

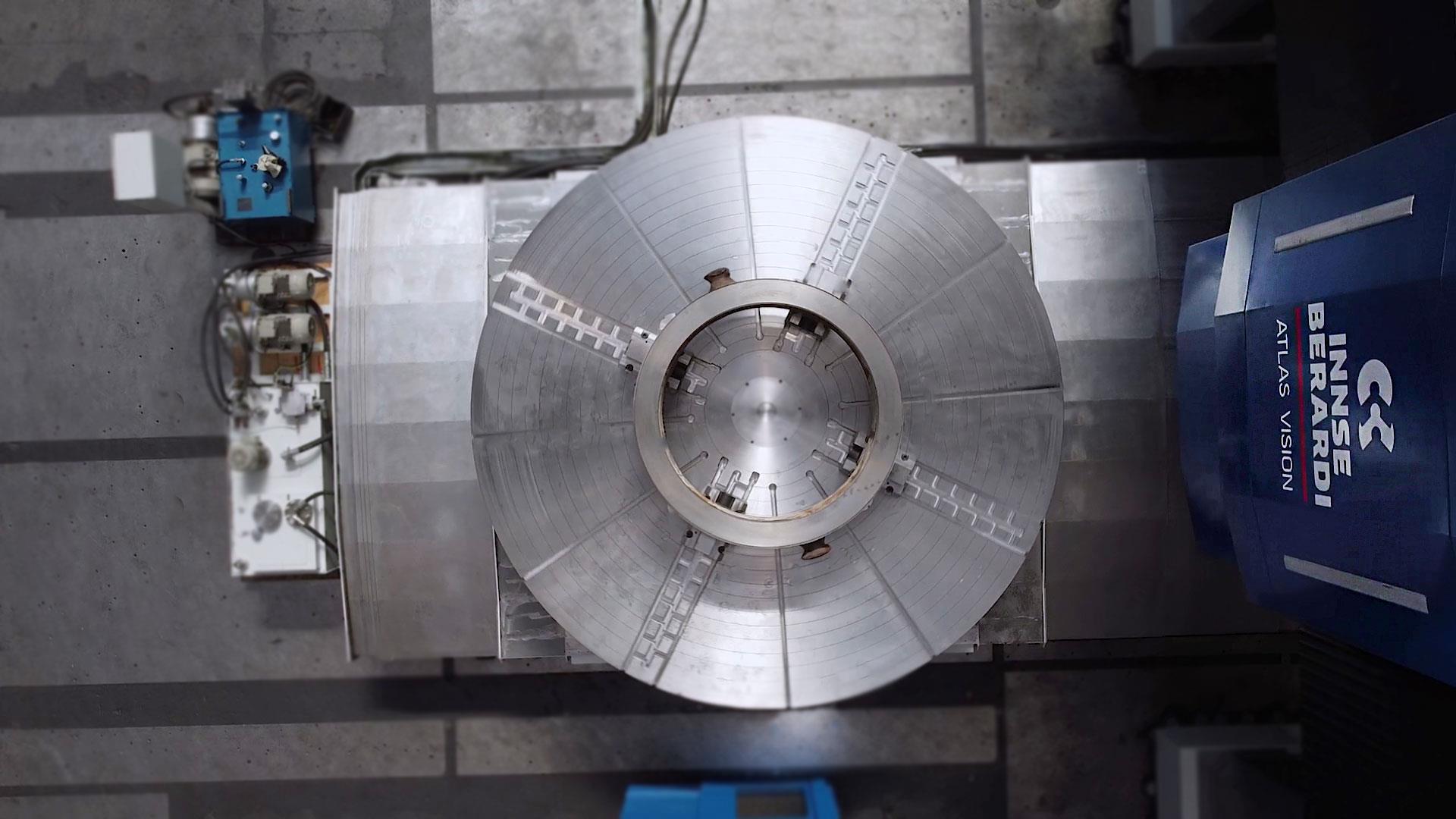

The Turning table, part of Innse-Berardi's historical hydrostatic products, is equipped with two torque motors coupled with range gears that also work in master and slave mode to ensure maximum accuracies and at the same time, excellent technological parameters.

The table is capable of supporting an unbalanced load due to our advanced detection system, that further enhances the technologic value offered.

| Distance between spindle nose and table plate | 0 ÷ 3.000 mm |

| Turning/milling table diameter | 4300 mm |

| Maximum workpiece diameter that can be turned | Ø5500 mm |

| Maximum load capacity | 100 ton |

| Table longitudinal travel (X axis) | 3000 (+ 2.900 / - 100) mm |

| Table rotation speed in turning | 1÷60 |

| Table rotation speed in milling | 0÷3.2 |

Accessory heads:

Accessory heads complete the supply. The universal head with motorized continuous position is the result of continuous improvements that guarantee customers save time during axis orientation. This translates into greater machining availability and more productivity through the machine's life.

| Main spindle | MF50-CB-I50 |

| Turning head | TH2-C8 |

| Universal head with continuous positioning | TUA45-CB-I50 |